-

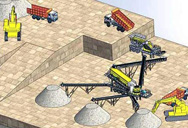

Мобильная дробилка

- методы добычи железной руды австралай

- шаровая мельница с центральнй разгр

- завод по переработке камня для продажи

- вариатор бесцентрового шлифования

- камешка дробилка производитель в ФИЛИППИНАХ

- заключение на переработку руды

- лента для вакуумных фильтров

- фото камнедробилки в горах

- каменная дробилка для золотой руды

- большой горное оборудование Африка

- машины загрузки и хранения товаров

- мобильныи каменная дробилка цена индию

- Зенит оборудование ленточные ролики

- 2017 A новый камень конусная дробилка для продажи

- карьер на продажу 2cmagnesium

- температура цемента на мельнице ола

- дробилки щебня и гравия

- высокоэффективная машина для производства песка по разумной цене

- стандартная конусная дробилка мощность

- Ашигласан jaw crusher jaws

<молотковая мельница подачи машины

CJ409 颚式破碎机

Stationary jaw crushers CJ409 颚式破碎机 Feed opening 895 x 660 mm (35 x 28 in.) mm Motor power 75 kW (100 hp) 山特维克 CJ409 颚式破碎机采用重型设计,具有出色的可靠

Read More

Industrial Solutions Jaw crushers - ThyssenKrupp

2022.11.21 Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being

Read More

Terex Minerals Processing Systems JW SERIES JAW

2023.7.14 The jaw crushers handle ores, rock, gravel and recycled concrete. Each machine is backed by the Terex® Minerals Processing Systems total after-market

Read More

Jaw Crushers - FAQ - Comprehensive Jaw Crusher Guide

A jaw crusher is a crucial component in mining and ore processing plants, performing the primary crushing of rock and mineral ore to reduce and control the size of materials for

Read More

Influence of jaw crusher parameters on the quality of

2020.6.1 Product quality is measured in terms of particle shape and mechanical properties. The crusher and feed parameters used are closed side setting (CSS), speed,

Read More

Product datasheet Essa® JC3000 Jaw Crusher - FLSmidth

2023.7.6 A well-proven single toggle jaw crusher, the Essa® JC3000 is a heavy-duty, low-maintenance machine. It readily accepts soft to very hard ore, drill core, rock and

Read More

Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher

Features. Hydraulically adjustable jaw setting. to maximize your output. Reverse crushing action. to crush sticky material or relieve blockages. Hydraulic drive. enabling the crusher

Read More

thyssenkrupp jaw crusher thyssenkrupp Polysius

Advantages at a glance: high throughput rate. optimized crushing chamber resulting in reduced wear and long lifetime. advanced kinematics of swing jaw. reinforced design of swing jaw to take up peak loads. crushing jaws

Read More

Cedarapids JW42 Jaw Crusher - Terex MPS

2024.4.18 The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42” x 20’ (1067 x 6096 mm) vibrating grizzly feeder resulting in a high

Read More

Jaw Crushers - Parker Plant

6 天之前 The chassis is complete with access/maintenance platforms to the crusher and power unit and a main operator platform overlooks all stages of operation. RE model Conforms to European design standards for road use; High capacity 'Rocksizer' or 'RockSledger' Jaw crusher; Improved high performance manganese jaws; Heavy duty

Read More

Jaw Plates: Everything You Should Know Crusher

2023.2.16 What’s A Jaw Plate. Jaw plates are the parts of the jaw crusher that direct contact with the material being crushed. They are rectangular in shape and are designed to fit around the crushing

Read More

Nordberg® C Series™ jaw crushers - Metso

The core of Nordberg® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house

Read More

Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher

1,200 x 750 mm (47 x 29 in.) Max. feed size. 650 mm (26 in.) Capacity. 400 mtph (440 stph) Sandvik QJ341 mobile jaw crusher is the ideal solution for a wide range of applications. Equipped with a C12 jaw crusher, a powerful and fuel-efficient engine, it is designed to tackle the most difficult operations. QJ341.

Read More

What Is a Jaw Crusher? – Sandrock Mining

2023.2.27 A jaw crusher is a primary crusher used in crushing processes that involve large pieces of material. It is designed to reduce the size of the material for further processing or use. Jaw crushers are typically used in the mining, construction, and demolition industries. The jaw crusher has a fixed jaw and a moving jaw.

Read More

Nordberg® C96™ jaw crusher - Metso

Nordberg® C96™ jaw crusher is a compact primary crusher engineered to perform for a long time. It is designed to be reliable and simple to operate. Assembled from convenient sized pieces, the crusher is easily dismantled for transport and reassembled if required. This jaw crusher shares many of the same features as other jaw crusher models ...

Read More

Jaw Crusher: What Is It How Does It Work? - Vykin

2024.4.18 A jaw crusher is a machine that breaks down large rocks into smaller pieces of rock, gravel, or dust. It does this by placing two jaw plates perpendicular to each other and squeezing the rock between them until it is broken into small pieces. A stationary jaw plate and a movable jaw plate control the movement of these jaw plates.

Read More

Jaw Crushers - AGGRETEK Jaw Crushers for aggregate

The closed side setting can be adjusted using shim plates with hydraulic power. AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling. Typical applications for jaw crushers are; Reversable high manganese cast steel jaw plates. Different profiles are available for different rock types.

Read More

Jaw Crusher Explained - saVRee

Jaw crushers are sized based upon the dimensions of the top feed inlet (gape) or the dimensions of the jaws. For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width.

Read More

Understanding Jaw Crusher Parts and Their Functions - AGICO

2023.2.23 Introduction: Jaw crushers are powerful machines that are widely used in the mining, quarrying, and recycling industries. These machines are designed to crush large rocks and ores into smaller pieces for further processing. A jaw crusher consists of a fixed jaw and a movable jaw, with the latter being driven by an eccentric shaft that moves the

Read More

Jaw Crusher BB 200 - RETSCH - rapid and gentle

The Jaw Crusher BB 200 is a floor model designed for a throughput of up to 300 kg/h, suitable for many typical crushing tasks. It accepts feed sizes up to 90 mm. The gap width can be set stepless from 0-30 mm. Depending on

Read More

Jaws Mini combo Crusher – Jaws Mini Crushers

The Jaws Mini Crusher is designed to deal with a multitude of site waste, reducing all materials to skips, reusing them on site or even being sold on as a usable product!Never before has a machine been so versatile. The

Read More

The Ultimate Guide to Jaw Crushing Machines:

2023.2.21 A hydraulic jaw crusher is a type of jaw crusher that uses hydraulic pressure to crush materials. It has a movable jaw that is operated by an eccentric shaft, as well as a fixed jaw that is positioned opposite

Read More

Understanding Types of Jaw Crusher: A Comprehensive

2024.2.6 Blake jaw crushers, also as double toggle jaw crushers, are characterized by the position of the pivot of the swing jaw, which is located at the top of the machine. This design allows for a larger feed size and a higher capacity, making it suitable for primary crushing. The motion of the swing jaw in a Blake crusher is predominantly vertical ...

Read More

QJ241 Mobile Jaw Crusher - Compact Jaw Crusher - SRP

Max. feed size. 520 mm (21 in.) Capacity. 225 mtph (248 stph) Sandvik QJ241 mobile jaw crusher is the most compact machine in the series and is ideal for smaller operations. Like the rest of the range, it delivers maximum productivity with low operating costs, and has been designed with the user in mind.

Read More

Jaw Crusher Parts Aftermarket Wear and Spare Parts GTEK

3 天之前 Manganese Liners for Jaw Crusher. The jaw plates and the cheek plates are the most common wear parts that need to be replaced frequently. GTEK is able to produce jaw plates with different tooth shapes and materials as per your request. Typical metallurgical options: Cheek plates: Mn13Cr2. Jaw plates: Mn13Cr2, Mn18Cr2, Mn22Cr2.

Read More

Jenis-jenis Jaw Crusher – Alat Preparasi Nikel

Alat Preparasi Nikel – Jaw crusher diperkenalkan oleh Blake dan Dodge , dan beroperasi dengan menerapkan penghancur bertekanan. Merupakan salah satu peralatan pemecah batu yang paling terkenal di dunia. Jaw Crusher sangat ideal dan sesuai untuk penggunaan pada saat penghancuran tahap pertama dan tahap kedua. Memiliki kekuatan anti

Read More

Herzog Maschinenfabrik: Crushing

Depending on the material being crushed, the jaw crushers can be supplied with crushing jaws made of different materials. One characteristic of jaws made of manganese steel is that they harden further over time with increased use. ... There is no alternating working stroke and no-load stroke as occurs with the jaw crusher. close. Service. World ...

Read More

Efficient Jaw Crusher for Coal Analysis - Insmart Systems

Working Principal of Jaw Crusher. Lumpy test material to be crushed is fed into the crushing zone through a hopper. The crushing zone consists of two parallel side walls of hardened and tempered steel and two special profile Jaws. One jaw is provided with oscillatory motion, whereas the other jaw is hinged to adjust the gap and get desired ...

Read More

Jaw Crusher 3D CAD Model Library GrabCAD

2021.4.2 Jaw Crusher. Enkhbayar Byambaa. April 2nd, 2021. Hope you this will help you. Download files. Like. Share. 1109 Downloads 60 Likes 10 Comments.

Read More

Retsch : 产品 : 粉碎设备 : 颚式粉碎仪

颚式研磨仪应用领域. A jaw crusher is always at the very front of the sample preparation chain, precrushing all hard and brittle materials. The RETSCH jaw crusher range is primarily used in laboratories and pilot plants under

Read More

Jaw Crushers Kenmore

Jaw Crusher Spares. Kenmore Group of Companies is constantly striving to improve the design and quality of our jaw crusher liners and spares to offer you improved life, reliability and quality at affordable prices, we stock a

Read More

Nordberg® C160™ jaw crusher - Metso

Nordberg® C160™ jaw crusher is designed to be extremely reliable. Its equipped to meet the expectations of customers who run their primary crushing plants 24 hours a day. Based on customer experience and comprehensive testing, the critical areas of Nordberg® C160™ jaw crusher are protected against wear. The vital parts are also quickly ...

Read More

Jaw Plates Premium Manganese Liners GTEK MINING

6 天之前 We offer jaw plates in 13%, 18%, and 22% grades of manganese, with chromium ranging from 2% to 3%. Additional element additions can be customized upon requirements, such as Mo0.5 (molybdenum) or ceramic inserts. We keep a chemistry inspection report for each order, even each jaw plate, for quality tracking purposes.

Read More

Jaw Crushers Manufacturer Puzzolana

6 天之前 Jaw Crushers. Designed to crush ROM feed material for demanding quarrying, mining, and demolition purposes. With their unique Elliptical motion of the swing jaw Crushers, ensure highly efficient production rates at any setting.

Read More

Crusher Buckets – Jaws Mini Crushers

Crusher bucket designed to be applied to operating machines such as wheel loaders, skid steer loaders, backhoe loaders and excavators, it is capable of crushing any type of inert material, transforming it into ready-to-use material directly on site. Highly versatile and high-performance, it meets all crushing needs, in small and medium-sized ...

Read More

Jaw Crusher Premiertrak 400X R400X Powerscreen

3 天之前 Tier 3: 46,500kg, Tier 4F 46,650kg, Tier 4F Pre-Screen: 48,030kg. The Powerscreen® Premiertrak 400X range of portable jaw crushers are designed for medium scale operators in quarrying, demolition, recycling and mining applications. The range includes the Premiertrak 400X with hydraulic adjust and the Premiertrak R400X with

Read More

What Is A Jaw Crusher? - Caldas Engineering and

A jaw crusher, as its name suggests, operates much like how our jaws work when we chew. It is a vital piece of equipment that is used for the initial process of mineral processing. Let’s delve deeper into the structures, operation and uses of this invaluable machinery. Structure And Operation. A jaw crusher primarily consists of two plates ...

Read More

J-1160 Primary Mobile Jaw Crusher Tracked Crusher Finlay

2024.4.11 The second generation Terex Finlay J-1160 Primary Mobile Jaw Crusher was designed with the customer and operator in mind. The machine has been designed with increased under jaw clearance and all round preventative maintenance and serviceability access. The heartbeat of the machine is the renowned and aggressive Terex 1000 x

Read More

Jaw crusher parts - Metso

Jaw crusher wear parts are designed for processing all rock types in surface and underground operations. Our offering consists of jaw plates such as different one-piece jaws and two-piece jaws as well as cheek plates. Due to the wide range of applications and feed materials, our jaws are available in several different designs and alloys.

Read More