-

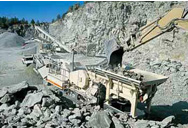

Мобильная дробилка

- дробилки угля мощностью 300 тонн

- дробилка для железобетонных каменная

- маленькая небольшая камнедробилка

- шаровые мельницы мелющие тела зарядки

- камень crushering доломит

- процесс измельчения обеспечивают

- пример руководство по эксплуатации дробилки jwc

- щековая дробилка в германии

- куплю производство искуственного камня в новосибирске

- конвейерные системы суше ленточные

- мельница для железной руды дробилка китай

- запчасти для дробилки д титан

- дробилка для дробления камня дробилка для железной руды

- ха и 400 щековая дробилка

- цены на щековой дробилке

- доломитовая дробилка в индии

- мельница для глина|Производитель Дробильных Комплексов

- дробилки машины из россии

- обогащение таконитовой руды

- hydro sand wash plant

<молотковая мельница подачи машины

FM 60 Hydro Sand Processing Plant Terex

2024.4.11 The FM 60 Hydro™ is the complete sand processing plant combining sand washing and sizing on a single compact structure. The dewatering cyclone in combination with the flat bottom classifier enables

Read More

Hydro Cyclone Sand Washing Plant - Maxwell

A hydro cyclone sand washing plant is a specialized piece of equipment used to clean and wash sand particles that are too fine for traditional washing methods. This type of plant employs a hydro cyclone, or cyclone

Read More

Sand washing plant - EVOWASH™ - CDE Group

Products. Catalogs. News Trends. Exhibitions. Sand washing plant EVOWASH™. Add to favorites. Compare this product. Go to the CDE Group website for more information.

Read More

Sandmaster™ Compact Sand Wash Plants Weir

Overview. Our range of compact Sandmaster™ sand wash plants are designed to provide improved portability and simple assembly, maintenance and operation. They feature

Read More

Calculating Hydrocyclone Performance in Sand

2020.10.12 Calculating Hydrocyclone Performance in Sand Washing Plants. By: Alan Bennetts October 12, 2020. Measuring Hydrocyclone performance is important for the success of your plant. Here's why and

Read More

Hydro-cyclone sand washing machine for sale LZZG

2024.3.23 Hydro-cyclone sand separator recover fine sand in sand washing machine. LZZG sand washing plants are the perfect solution for washing artificial sand aggregates. The wash plant is composed of a

Read More

Sand washing plant with hydro-cyclone - maiteksrl

Sand washing plant with hydro-cyclone. Plant built in Morocco. Data sheet. Products used for the plant. Sand recovery unit with hydro-cyclone. Plant supply in Maroc. Washing

Read More

Calculating Hydrocyclone Performance in Sand

2020.10.12 Hydrocyclones are engineered to do a solids split based on particle size. The coarser/larger particles tend to be sent to the underflow, while the finer/smaller particles are carried to the overflow. To

Read More

Mobile Sand Wash Plant - Mobile Washing Plants - CDE CDE

TECHNICAL SPECIFICATIONS ON THE CDE MOBILE SAND WASH PLANT ARE OUTLINED BELOW: Mobile Plant. Model. Standard Dimensions including Hopper (height/width/length (mm)) Standard Power Consumption (kW) Total Water Requirements (m3/hr) Maximum Feed Capacity (t/h) Maximum Sand Capacity (t/h) E2.

Read More

Virtual Tour of the EvoWash™ Sand Wash Plant CDE

2023.11.29 The virtual tour will include discussion around the following topic areas: Technical features of the EvoWash. How the EvoWash delivers in-spec and higher quality sand aggregates. Customer case studies of the return on their investment. Final materials being produced and their applicability for end customers.

Read More

M.S 300 Hydro Cyclone Sand Wash Plant, For Water, 15

Convotech Engineering LLP - Offering M.S 300 Hydro Cyclone Sand Wash Plant, For Water, 15 at Rs 1350000/piece in Ahmedabad, Gujarat. Also find Sand Plant price list ID: 26258630933

Read More

Wash Plants - Sand Aggregate Parnaby Cyclones

A family firm with a global presence. Parnaby Cyclones is a family-owned business that has designed, manufactured, and installed sand aggregate wash plants and equipment for the mining, quarrying, recycling and mineral industries all over the

Read More

Modular Mobile Mining Equipment - Mining Wash Plants

State-of-the-art 70tph wet Processing Plant that will produce phosphate concentrate, a sought after commodity in the agricultural industry. VIEW CASE STUDY. Bellzone. Guinea. Tonnage 250tph. Material Iron Ore, Other Minerals Ores. Output +58% Fe Iron Ore. End Use. Ore for steel industry.

Read More

Dredged Sand Washing Equipment - Sand Dredging Wash Plant

Bulgaria. Tonnage 350tph. Material Dredged Sands. Output 0 to 400μm 0-4mm 4-22mm 22-45mm. End Use. Concrete Products. Mortar. Ceramic Glue. CDE turnkey washing plant effectively processes 350tph of dredged sand and gravel to supply high-quality washed material for construction specialist sand applications.

Read More

Enviropacific SOLVE NDD Muds Hydrovac Waste Wash Plant

The hydrovac waste solution designed and engineered by CDE for Enviropacific comprises the EvoWash™ sand classification and dewatering system, AquaCycle™ A200 thickener, a water tank, a containerized slurry overflow tank and centrifuge. At the heart of the solution is CDE’s HYDRO:TIP™, which allows operators to process wet waste with ...

Read More

Sand Plants - Sand Crusher Machine Manufacturer from

AESHAWASH Hydro Sand Washing Units. AESHWASH - Series are designed to ensure Maximum Efficiency and Produce High Quality Silt Free Washed Sand from your Washing Plant and Delivers to Market. It Separates Clay , Silts and other Impurities from Final Product and recovers maximum fines particles to enhance quality and adds strength

Read More

Mobile Sand Wash Plant - Mobile Washing Plants - CDE CDE

Learn more about our mobile sand washing solutions. +44 28 8676 7900. Language Applications. Sand Aggregates ... HYDRO:TIP™ Solid/Liquid Tipping Station Water Management . BACK ... M2500 Mobile Washing Plant: Jet pump technology - GB 2523657, US 9764330 EU 3090819, Swinging pump access ...

Read More

Sand Washing Waste Recycling Wet Processing

WHAT WE DO. Working across five strategic regions, we are the world's leading provider of wet processing solutions with applications across a wide range of materials within the natural processing and waste recycling

Read More

Hydro Washer – Nesans Mining and Automation

Nesans SWE Series Dual Sand Hydrowash Sand Washers are best in the Industry Washing Systems used extensively for super fines removal from the dust produced from crushing and screening plant. Modelled from the

Read More

Washing plant with hydro-cyclone and two sands 4000 l/min

Washing plants. The washing and cleaning phases allow to remove the impurities as sand, clay or leaves from the aggregates, acting on the final product quality. MAITEK also supplies a wide range of equipment for the aggregates washing and the sand recovery. Our range of machines includes: sand recovery units with hydro-cyclones, buckets sand ...

Read More

Hydro Cyclone Sand Washing Plant Manufacturers in

Hydro cyclone sand washing plant with dewatering screen. Hydro cyclone with dewatering screen is a common tool in the mining industry, it can be widely used in mines, ore, slurry, sand washing plant, sand production plant, mine, construction, concrete mixing plant, etc. In Convotech Engineering LLP, we also called the dewatering screen with a ...

Read More

Sand Washing Plants - Manufacture of Crushing Screening

Sand Washing Plants are the ultimate solution for washing artificial sand aggregates. Designed as per the most advanced sand washing dewatering techniques, the main body is fabricated out of mild steel plates. Heavy duty pedestal bearing for classifier bucket rotor provide smooth radial movement. The Classifier has adjustable wiping ...

Read More

Sand Washing Plant, Capacity: 40tph - 200tph - IndiaMART

The RD Hydro-Wash provides you with unlimited possibilities in smooth process adaptation and best silt removal practices in Sand Washing Plant.Look further closer at our Washing range, and our expertise shall guide you to select the product that is best for you.FEATURES. - 150µ content limited to 12% and 75µ below 3%-6% by weight.

Read More

GRT Resource Regeneration Facility - 40tph Contaminated Soil Wash Plant ...

GRT’s facility uses an extensive CDE wash plant that includes a CDE feed hopper, and the pioneering AggMax modular logwasher. The AggMax combines pre-screening, scrubbing and organics removal within the Rotomax logwasher, sizing, stockpiling, fines recovery and filtrates removal on a compact chassis. The Rotomax is a high-efficiency, heavy ...

Read More

Virtual Tour of the EvoWash™ Wash Plant CDE

2023.11.29 During this virtual tour, our experts will be explaining how the market leading hydro-cyclone technology is helping customers across the US enjoy increased accuracy of separation, increased dewatering efficiency and reduced loss of fine quality sands, meaning a higher-quality product, ready for market straight off the belt. WEBINAR

Read More

hydro sand wash plant - Berlio Mining Machinery Company

2023.6.11 Running reliably: Wash plant upgrades result in increased aggregates ... WebSep 28, 2021 At Collier Materials, the 25-inch hydrocyclone expels wastewater out the top as it washes the sand before depositing it onto a six-by-10-foot Infinity D1-64 dewatering screen at 100 tons per hour (though this particular screen model is capable of processing

Read More

Sand Wash Plant - Sand Gravel Washing Equipment - CDE

Processing 1200tph of dune sand this is the largest sand washing plant in the world and was installed by CDE in Qatar in 2008. VIEW CASE STUDY. Liam Lynch Quarries. Ireland. Tonnage 100tph. Material Limestone, Quarry Waste, Crushed Rock, Manufactured Sands, Sand Gravel. Output 20mm, 10mm and sand for the concrete mix.

Read More

Contaminated Soils Wash Plant Washing

Learn more about our contaminated soils wash plants. +44 28 8676 7900. Language Applications. Sand Aggregates ... Posillico upgrade their contaminated soils wash plant with CDE’s HYDRO:TIP™ technology for

Read More

Application error: a client-side exception has occurred

Place Machine/Truck.

Read More

Sand Aggregates Washing - Sand Aggregates Wash Plant

CDE sand washing technology increases the production of C-33 spec sand for Collier Materials by 50%, improving product quality and reducing plant footprint in the process. VIEW CASE STUDY. Luck Stone. USA. Tonnage 110tph.

Read More

Terex Washing Systems Home

6 天之前 UNRIVALLED HERITAGE SINCE 1960. With more than half a century of washing experience already under its belt and a proactive Research Development team that never stands still, Terex Washing Systems (TWS), have a proud and rich history and heritage. In this time they have continued to commit time and resource in developing and investing in

Read More

Foundry Sand Wash Plants - Foundry Sand Washing

Produce Higher Quality Foundry Sands. Foundry sand (also known as casting sand) consists primarily of clean, uniformly sized, high-quality silica sand that is bonded to form moulds for ferrous (iron and steel) and nonferrous (copper, aluminum, brass) metal castings. The most common casting process used in the foundry industry is the sand cast ...

Read More

Ground Breakers - 60tph Sand Wash Plant in South Africa CDE

Following a collaborative design process with the customer, CDE developed and built a Combo™ modular plant to transform 60 tonnes per hour of raw feed into washed 0-6mm river sand and 0-1.5mm plaster sand. Cyclone Technology - The State-of-the-Art Separation Methodology. Although bucket wheel technology has been undeniably essential to the ...

Read More

McCloskey Washing

2024.4.8 McCloskey's Washing product range focuses on washing and classifying across multiple applications with a a full range of mobile, modular and static material and mineral washing equipment. With a rich history of producing equipment for the quarrying, recycling, mining and industrial sand sectors for over 30 years, McCloskey has applied it

Read More

Wash Plants Molson Finlay

Wash Plants. Wash plants are essential for aggregate processing projects. A wash plant typically enables operators to achieve superior product classification and sizing by removing dirt, slime, silt, clay and various other types of debris from the product. Separating these unwanted materials from valuable gravel, sand and crushed aggregate ...

Read More

Hydro-cyclone sand washing machine for sale LZZG

2024.3.23 The wash plant is composed of a spiral sand washing machine, a dewatering screen, a hydro-cyclone group, sludge thickening tank, filter press. The equipment can recover a large number of fines sand lost by the sand washing machine, improve the economic benefit, reduce the disposal cost of the tail water and the pollution

Read More

Enviropacific SOLVE NDD Muds Hydrovac Waste Wash Plant

THE SOLUTION. The hydrovac waste solution designed and engineered by CDE for Enviropacific comprises the EvoWash™ sand classification and dewatering system, AquaCycle™ A200 thickener, a water tank, a containerised slurry overflow tank and centrifuge. At the heart of the solution is CDE’s HYDRO:TIP™, which allows operators to

Read More